Home »

Blog » QI Macros » Page 21

Improvement Insights Blog

Latest "QI Macros" Posts

The recent collapse of GE stock price has led to a lot of discussion. Here’s my two cents.

Jack Welch implemented Six Sigma at GE which drove many CEOs to do the same. From scuttlebutt I’ve picked up over the years, this lead to crazy rules like every employee had to do two Six Sigma projects a year. This would violate Pareto’s Rule: if only 20% of the business is creating 80% of the defects, waste and rework, having employees try to fix the remaining 80% of the business is a waste of resources. Six Sigma needs focus, not spread.

Jeffery Immelt reduced leadership support for Six Sigma.

Continue Reading "GE’s Problems – Strategy or Six Sigma?"

Posted by Jay Arthur in QI Macros, Six Sigma.

This recent article talks about how GE measured Six Sigma success:

“Engineers and scientists were measured on how many Six Sigma projects they completed during the year.”

Since I know that 4% of the business is causing over half of the waste, rework and lost profit (the 4-50 rule), making everyone do “Six Sigma projects” is a form of overproduction (violating a Lean rule). It creates waste, rework and unhappy employees. It makes people put trivial improvements in Six Sigma format to achieve the goals.

Measure Six Sigma success by bottom-line, profit and productivity enhancing results, not projects. Use data to focus improvements to maximize results and minimize effort.

Continue Reading "Measuring Six Sigma Success"

Posted by Jay Arthur in QI Macros, Six Sigma.

Lean Six Sigma Fundamentalists believe:

– Get management commitment

– Train lots of black and green belts

– Implement wall-to-wall floor to ceiling

Lean Six Sigma Revolutionaries believe:

-Engage informal leaders

-Train money belts

-Laser-focused, data-driven breakthrough improvements

Continue Reading "Lean Six Sigma Fundamentalists vs Revolutionaries"

Posted by Jay Arthur in QI Macros, Six Sigma.

The next time you hit a glitch are you going to

0. Ignore it

1. Find a work around

2. Take heroic action to fix it.

3. Fix the glitch and then take the time to prevent it from ever happening again?

Continue Reading "Glitches are Opportunities"

Posted by Jay Arthur in QI Macros, Six Sigma.

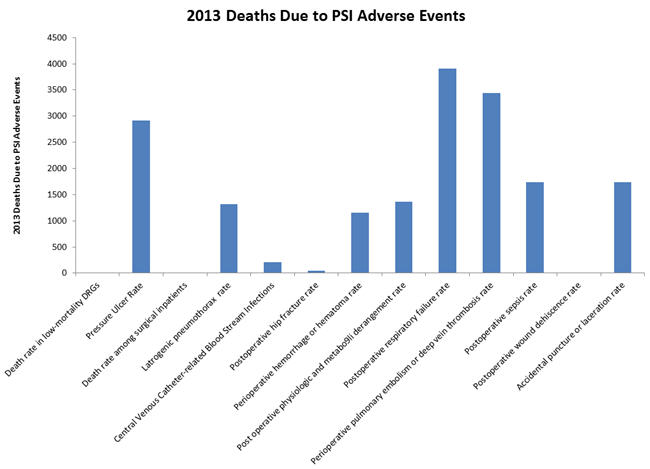

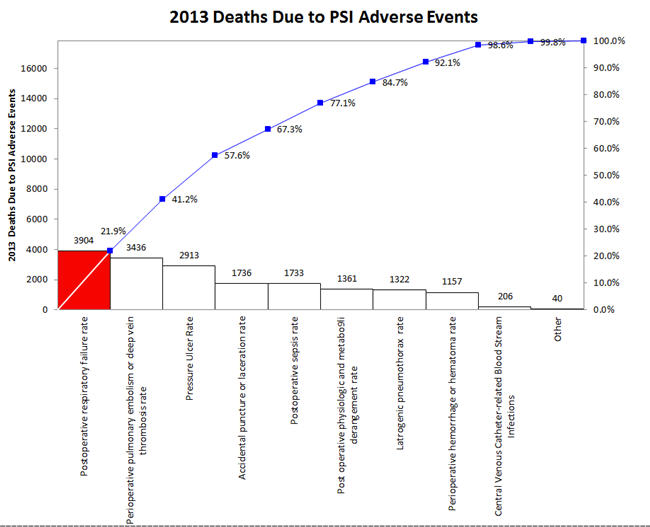

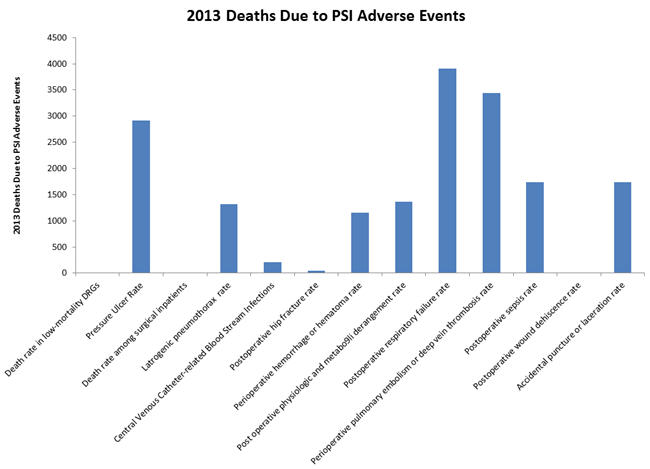

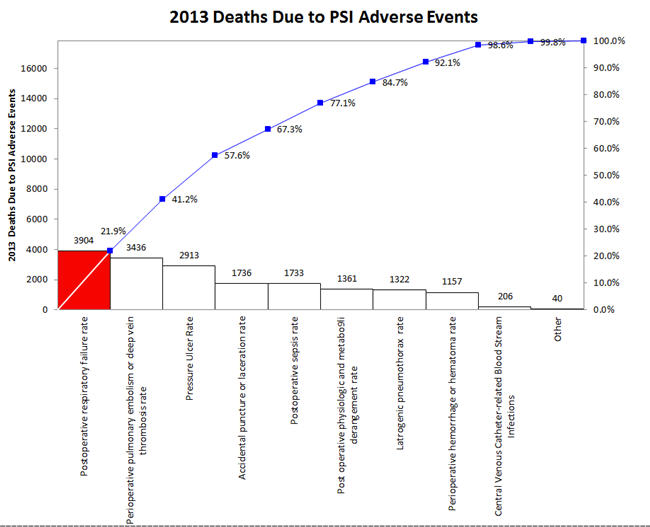

The July/August 2017 HealthLeaders magazine had a series of charts about the impact of Adverse Events. In general, the magazine used column charts:

But wouldn’t a Pareto chart illuminate the important adverse events more clearly? The first three accounted for over 57% of 2013 deaths.

Continue Reading "Excel Bar Charts Hide The Signal in Noise"

Posted by Jay Arthur in Excel, QI Macros, Six Sigma.

I have found that an XmR chart is the easiest way to display attribute data. Simply convert the numerator/denominator into a ratio and plot the ratio.

- defects per day could be a c chart, but an XmR chart works just as well

- defects/samplesize could be np, p or u chart, but XmR chart works just as well using the ratio

Almost two decades ago, Tom Pyzdek said: X chart provides an excellent approximation to the p chart.

More recently, Donald Wheeler noted that XmR chart limits will be very close to c, np, p or u chart limits if the underlying distribution is correct.

Continue Reading "Use XmR Charts instead of c, np, p and u Charts"

Posted by Jay Arthur in QI Macros, Six Sigma, Statistics.

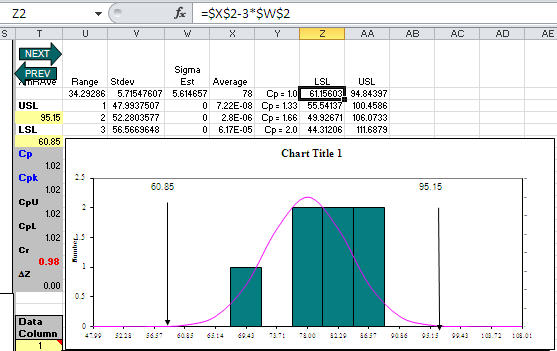

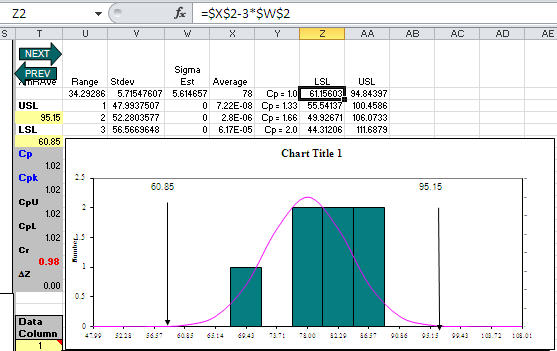

Customer asked me what seemed like a strange question: What specification limits do I need to get a Cp greater than one? Usually her customer should set specification limits, but her boss wanted to know what they could deliver. Hmmmm!

Then I realized that since QI Macros templates (e.g., XmR chart) calculate the average and sigma estimator, the LSL/USL for Cp = 1.0 would be:

LSL = Average – 3*SigEst USL = Average+ 3*SigEst

For Cp = 1.33, just change the 3 to a 4; Cp = 1.66, change the 3 to a 5. Here’s an XmR chart template with some sample data and calculations to reverse engineer spec limits:

Continue Reading "What USL/LSL Do I Need for Cp>1?"

Posted by Jay Arthur in QI Macros, Six Sigma, Statistics.

A customer called upset about Cpk. He had a runout of 0.010, but was getting a very low Cpk. Turns out he’d made the classic mistake of confusing a hard limit (e.g., zero) with a specification limit. I had him use QI Macros with an Upper Specification limit (USL) and no Lower Specification Limit (LSL). His Cpk immediately jumped to a more expected value of 1.78.

Later in the day another customer asked why Cpk is calculated as the minimum of the upper or lower Cpk? Because you use the one closest to the average. I think that customer may have had the same problem, confusing a hard limit with a specification limit.

Continue Reading "Cpk and Hard vs Specification Limits"

Posted by Jay Arthur in QI Macros, Six Sigma.

Many people avoid Six Sigma because they think it involves a lot of math and statistics. You know, formulas. I don’t think you need any formulas. You don’t need to be a statistician. You just need software that went to college and knows the formulas.

In The Math Gene, Author Keith Devlin explores “why so many people find mathematics impossibly hard.” He says: mathematics is the science of patterns. Isn’t that what we’re trying to do in Six Sigma, separate the wheat from the chaff, separate the signal from the noise and detect the underlying patterns of performance?

Continue Reading "Is Fear of Math Holding You Back?"

Posted by Jay Arthur in QI Macros, Six Sigma.

Nobody wants to read your spreadsheet! No matter how hard you try to make it pretty, create great labels or whatever, the only person who can read your spreadsheet is a CFO or Excel spreadsheet geek. And the Excel geek is going to tell you 10 ways to make it prettier.

The purpose of data is to provide insights for action, not just report past performance.

How Do I Know That Most Excel Users Try to Make Their Spreadsheets Readable By People?

According to Renu Davi, Sr. Program Manager for Excel, Microsoft tracks how people use Excel. The vast majority of the 650 million users use it for lists and reports.

Continue Reading "Nobody Wants to Read Your Spreadsheet!"

Posted by Jay Arthur in Data Mining, QI Macros, Six Sigma.