Home »

Blog » Lean » Page 7

Improvement Insights Blog

Latest "Lean" Posts

Are you skipping Six Sigma stones across the surface of your business or are you finding people who take to it like a duck to water. People who can dive beneath the surface to find the invisible low-hanging fruit?

“Have you ever skipped a rock across a lake? Maybe the first time you threw it out there it just went “sploosh.” Then you figured out that flatter rocks skip better, so you started throwing them out and they’d go “skip-skip-sploosh,” or maybe get three or four or five “skip-skips” and “sploosh.”

“Then a duck came flying in, put out its landing gear and just kind of eased into the water.

Continue Reading "Skipping Stones or Diving Beneath the Surface of Your Business?"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, QI Macros, Six Sigma.

Humans, by nature, have a fear of looking bad (FOLB). And we have a fear of looking stupid (FOLS). These are slowing COVID-19 response and quality improvement. Here’s why:

Hi, I’m Jay Arthur, author of “Lean Six Sigma Demystified” and QI Macros [software].

“You’ve all probably all heard some of these acronyms that are running around like FOMO: Fear Of Missing Out. Well, I wanted to introduce you to a couple more that I’d like you to consider. FOLB: Fear Of Looking Bad.

“Now when I’ve gone out to work with companies in consulting roles, some of these managers think, “I’m supposed to be in charge of fixing everything.

Continue Reading "FOLB – Fear of Looking Bad"

Posted by Jay Arthur in Healthcare, Improvement Insights, Lean, Manufacturing, Six Sigma.

We know that Lean can collapse cycle time by 75% or more. Here’s what that means for COVID-19:

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and QI Macros [software].

“If you’ve ever done any Lean projects, you know pretty much if the process is this long {gestures}, with Value Stream Mapping and Spaghetti Diagramming, you can collapse that by maybe 75%, 80%, 90%. You can actually reduce the cycle time for almost anything and do it easily.

“One of the things that is creating optimism for me is that a few years ago I worked with an aerospace manufacturing company, and typically to get a Request For Proposal through, it was 1.9 years for any new part.

Continue Reading "Lean Response to COVID-19"

Posted by Jay Arthur in Healthcare, Improvement Insights, Lean.

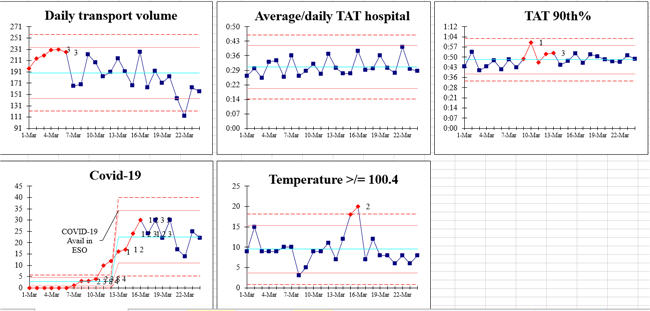

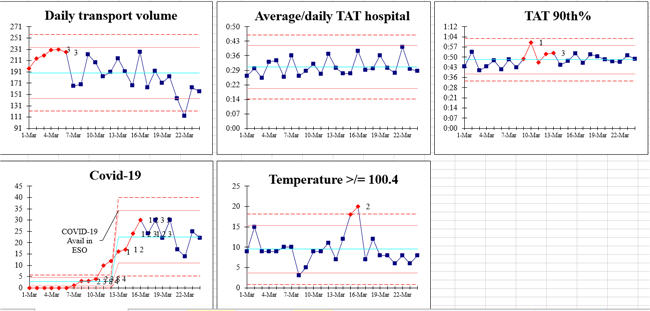

One of our QI Macros users offered to share his dashboard of paramedic response during the Seattle area response to COVID-19. His team transported the first COVID patient in America. As you can see, turnaround times (TAT) at the hospital averaged 30 minutes and temperatures spiked in transported patients.

Continue Reading "COVID-19 Paramedic Dashboard 2020"

Posted by Jay Arthur in Healthcare, Jay Arthur Blog, Lean, QI Macros.

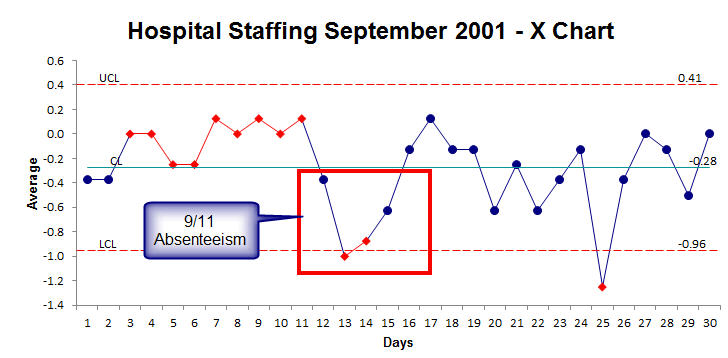

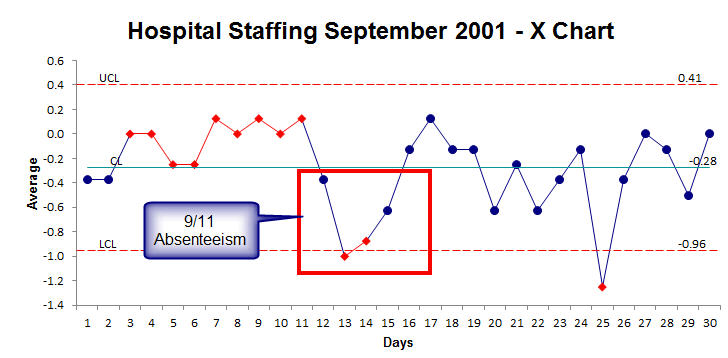

Back in 2002, thousands of miles from New York City, I worked with a hospital in Oregon. I was amazed to find that they had staffing data from 9/11 about the up and down for that month. As you can see in this X Chart, absenteeism (understaffing) was lower for each of the four following days, 9/12-15, and then recovered. I have noticed this pattern with COVID-19 as well: a week of paralysis followed by a return to normal. Unfortunately, healthcare workers haven’t had the luxury of downtime when dealing with the new crisis.

So don’t be surprised if crisis and uncertainty cause you or someone you know to hit the pause button.

Continue Reading "How Crisis Affects U.S. Healthcare Workers"

Posted by Jay Arthur in Healthcare, Jay Arthur Blog, Lean, QI Macros.

Out of Work? Need a job? Want to become indispensable to your employer?

Learn the data analysis skills for problem solving (a.k.a. Lean Six Sigma). Do it now. It’s Free!

Click here to get started: www.lssyb.com

“Hi, I’m Jay Arthur, author of “Lean Six Sigma Demystified” and the QI Macros [software].

“I don’t know about you, but right now, I’m staying home because of the directives around COVID-19. I know there’s a lot of people out there who have been displaced and are out of work, and now might be a good time to learn a new skill. I can tell you: being able to do some data analysis that results in problem solving is a skill that every, every, every business wants.

Continue Reading "Learn Data Analysis for Problem Solving"

Posted by Jay Arthur in Agile Lean Six Sigma, Data Mining, Healthcare, Improvement Insights, Lean, Manufacturing, QI Macros, Service, Six Sigma.

These are uncertain times. What’s the best way (both psychologically and as a group) to get though this? By you continuing to do what you do, whether it’s writing, coding, or continuing to improve the quality of the processes around you.

(And just to be clear, when I say, “Go out and do what you do,” I don’t mean to literally “go out” if you don’t have to… it’s just an expression. Please continue to take whatever steps are necessary to keep yourself and the people around you safe.)

“Hi, I’m Jay Arthur, author “Lean Six Sigma for Hospitals” and the QI Macros [software].

Continue Reading "What do we do? Do what you do."

Posted by Jay Arthur in Improvement Insights, Lean, Six Sigma.

Coronavirus means that we can’t wait weeks for training and months for improvements. Healthcare has to embrace Agile Lean Six Sigma to handle an infection that could overwhelm existing care facilities. (Hint: This has nothing to do with doctors and nurses, but everything to do with the patient.) Here’s how to do it:

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and the QI Macros [software]. You know, I think we’re at this place in time where we can no longer wait two to four weeks for training and four to six to twelve months for projects to get done.

Continue Reading "Agile Lean Healthcare Now"

Posted by Jay Arthur in Agile Lean Six Sigma, Healthcare, Improvement Insights, Lean, Six Sigma.

Ordered a snowthrower as a wedding gift for two day delivery. Eight days later it was delivered to someone’s home (not mine). How can we mistake-proof these kinds of problems?

“One of the guys in my office is getting married this June and so I got him an early wedding gift: a snow thrower. So I ordered it from Amazon. I ordered it on Monday, it was supposed to arrive on Wednesday; two days shipping on Prime.

“Then on Wednesday I get this notice that said, “Well, it’s sort of delayed.” So then it said maybe Friday, but of course on Friday it wasn’t here, and they tried to deliver it on Saturday, of course, which is when we’re closed.

Continue Reading "Snowthrower Delivery Debacle"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, Service, Six Sigma.

Nobody wants to look bad, which can make it impossible to make improvements. Here’s why:

“One of the things I’ve learned in all these years working in Quality Improvement is nobody, but nobody, wants to look bad. With the recent coronavirus [outbreak], the doctor who found that and [leaked news] out to the world, the Chinese government tried to shut him down, tried to keep that bit of information inside because they didn’t want to look bad.

“Well, this isn’t just a Chinese or Asian thing – saving face. In any business you walk into, somebody is in charge of how things are working and they’re in charge of trying to make it better, faster, cheaper.

Continue Reading "Nobody Wants to Look Bad"

Posted by Jay Arthur in Agile Lean Six Sigma, Healthcare, Improvement Insights, Lean, Six Sigma.