Home »

Blog » Lean » Page 13

Improvement Insights Blog

Latest "Lean" Posts

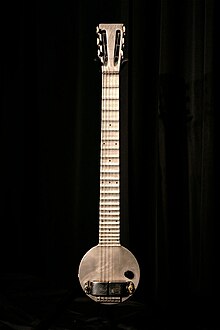

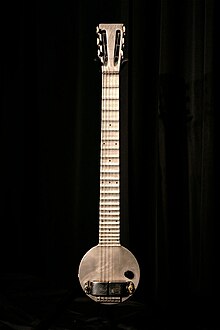

In 1931, George Beauchamp combined a guitar with a microphone to create the first electric guitar called the “Frying Pan.” Without it, we wouldn’t have rock-and-roll, country and blues. This is how transitions begin, with a prototype that catapults transition to a new way of doing things.

Isn’t it time to start doing the same thing with Lean Six Sigma? Not amplification, but acceleration?

Continue Reading "Agile Electric Guitar Development"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, QI Macros, Six Sigma.

HBR’s article on Agile At Scale predicts the future of business and Lean Six Sigma. Here’s what I learned:

Join my Agile Quality Improvement Movement. Sign up to receive Weekly Agile Six Sigma emails right in your inbox! Click HERE to subscribe.

Continue Reading "Agile Scaling Up In Corporations"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, QI Macros, Six Sigma.

The July-August, 2018 Inc. magazine has an article (pg. 22) about manufacturing vs supply chain service jobs. From 1999-2015:

- Manufacturing jobs declined from 12.5 million to 8.2. Supply chain jobs increased from 13.4 million to 20.0.

- Manufacturing salaries climbed only slightly from $54,800 to 59,800 while supply chain jobs rose from $72,600 to $85,200.

With increasing manufacturing automation, more jobs are being created around supporting production than actual production. Something to think about.

Continue Reading "Shift from Manufacturing to Supply Chain"

Posted by Jay Arthur in Jay Arthur Blog, Lean, Manufacturing.

I’ve lived through Business Process Reengineering which often stumbled because it was impossible to take a complex system and “reengineer” it. The only method I’ve found that works consistently is Agile Process Innovation. Here’s how it works:

Join my Agile Quality Improvement Movement. Sign up to receive Weekly Agile Six Sigma emails right in your inbox! Click HERE to subscribe.

Continue Reading "Agile Process Innovation"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma.

People often ask me, how big should an improvement team be? My answer: as small as possible.

In Fred Brooks’ Mythical Man Month, he points out that communication pathways increase in a nonlinear fashion. The formula is simple:

(n2-n)/2

Where n is the number of people on a team.

- 2 people = 1 connection (4-2)/2

- 3 people = 3 connections (9-3)/2

- 4 people = 6 connections (16-4)/2

- 5 people = 10 connections (25-5)/2

- 6 people = 15 connections (36-6)/2

- 7 people = 21 connections (49-7)/2

The bigger the team, the more time is spent on discussion and communication, not progress.

Continue Reading "Team Communication Costs"

Posted by Jay Arthur in Jay Arthur Blog, Lean, Six Sigma.

DMAIC is similar to software’s Waterfall methodology that has been replaced by Agile.

We can do the same thing with DMAIC. Here’s how.

Join my Agile Quality Improvement Movement. Sign up to receive Weekly Agile Six Sigma emails right in your inbox! Click HERE to subscribe.

Continue Reading "DMAIC from Waterfall to Agile"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, QI Macros, Six Sigma.

The cover of the May-June 2018 issue of Harvard Business Review highlights “Agile” as the future of business. This is the way business is going to stay competitive in the future. Speed is the killer app!

Lean Six Sigma can no longer cling to its old-fashioned way of doing things: weeks of training, months for improvement teams. Here’s why:

Join my Agile Quality Improvement Movement. Sign up to receive Weekly Agile Six Sigma emails right in your inbox! Click HERE to subscribe.

Continue Reading "Agile Lean Six Sigma"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, QI Macros, Six Sigma.

Last week, our grandson graduated from Colorado College and our granddaughter graduated from Rock Canyon High School.

Jake’s graduating class of 500 went single file to the podium to receive their diploma.

Rachel’s graduating class of 500 came from four directions simultaneously. Four name callers, four people handing out diplomas.

Which one do you think went faster?

Continue Reading "Lean Graduation Ceremonies"

Posted by Jay Arthur in Jay Arthur Blog, Lean, QI Macros, Service.

Do you know people who only dabble in Lean Six Sigma? They get in, get certified and get out?

You can use the tools of quality everywhere in your life and work for the rest of your life.

Why stop?

Join my Agile Quality Improvement Movement

Continue Reading "Going In and Out of Lean Six Sigma?"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma.