Home »

Blog » Jay Arthur Blog » Page 7

Improvement Insights Blog

Latest "Jay Arthur Blog" Posts

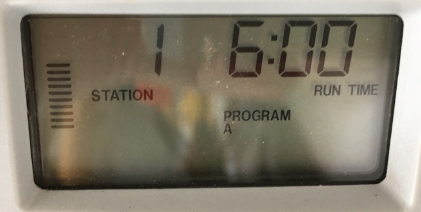

My water bill recently doubled. Turns out it’s a design flaw in my Hunter Pro-C controller.

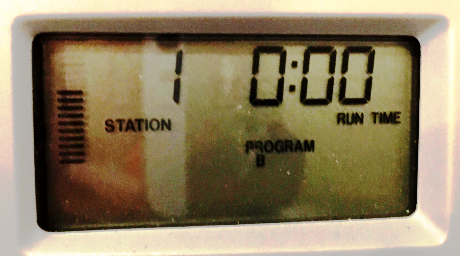

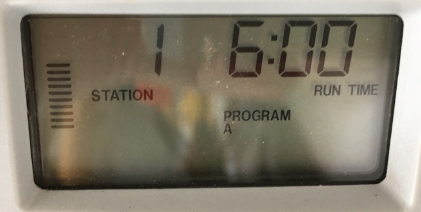

A while back, I set some of my zones to zero minutes.

But, if I accidentally hit the minus sign one more time, the controller goes to SIX HOURS:

It was a royal hassle, but I managed to submit an improvement suggestion to Hunter:

There should be no run times below ZERO! Duh!

I had Denver Water come out to show me how to read the meter.

- Meter reader basically said: “Meter’s correct. Fix your controller” and left.

What if they spent 5 minutes helping homeowners check their controller to find the problem?

Continue Reading "Hunter Pro-C Controller Problem"

Posted by Jay Arthur in Jay Arthur Blog, Six Sigma.

It looks like you’ve clicked on a link to learn about signing up for a webinar that’s already happened.

No worries, you can click HERE to find out about the next live webinar…

or you can click HERE to view a webinar that’s been recorded.

Continue Reading "Well, shoot! Looks like we missed each other!"

Posted by Jay Arthur in Jay Arthur Blog, QI Macros.

The July-August, 2018 Inc. magazine has an article (pg. 22) about manufacturing vs supply chain service jobs. From 1999-2015:

- Manufacturing jobs declined from 12.5 million to 8.2. Supply chain jobs increased from 13.4 million to 20.0.

- Manufacturing salaries climbed only slightly from $54,800 to 59,800 while supply chain jobs rose from $72,600 to $85,200.

With increasing manufacturing automation, more jobs are being created around supporting production than actual production. Something to think about.

Continue Reading "Shift from Manufacturing to Supply Chain"

Posted by Jay Arthur in Jay Arthur Blog, Lean, Manufacturing.

People often ask me, how big should an improvement team be? My answer: as small as possible.

In Fred Brooks’ Mythical Man Month, he points out that communication pathways increase in a nonlinear fashion. The formula is simple:

(n2-n)/2

Where n is the number of people on a team.

- 2 people = 1 connection (4-2)/2

- 3 people = 3 connections (9-3)/2

- 4 people = 6 connections (16-4)/2

- 5 people = 10 connections (25-5)/2

- 6 people = 15 connections (36-6)/2

- 7 people = 21 connections (49-7)/2

The bigger the team, the more time is spent on discussion and communication, not progress.

Continue Reading "Team Communication Costs"

Posted by Jay Arthur in Jay Arthur Blog, Lean, Six Sigma.

Are you making one of the most common mistakes in Six Sigma? Are you forgetting the control phase?

If you do forget to implement a control plan and control charts to monitor and corrective actions, you might just as well have not wasted everyone’s time.

Join my Agile Quality Improvement Movement. Sign up to receive Weekly Agile Six Sigma emails right in your inbox! Click HERE to subscribe.

Continue Reading "Forgetting The Control Phase?"

Posted by Jay Arthur in Improvement Insights, Jay Arthur Blog, QI Macros, Six Sigma.

Last week, our grandson graduated from Colorado College and our granddaughter graduated from Rock Canyon High School.

Jake’s graduating class of 500 went single file to the podium to receive their diploma.

Rachel’s graduating class of 500 came from four directions simultaneously. Four name callers, four people handing out diplomas.

Which one do you think went faster?

Continue Reading "Lean Graduation Ceremonies"

Posted by Jay Arthur in Jay Arthur Blog, Lean, QI Macros, Service.

ASQ World 2018, there were a lot of sessions about “Industry 4.0” and the transformation required by quality improvement professionals (Quality 4.0).

Wikipedia describes Industry 4.0 as: “the current trend of automation and data exchange in manufacturing technologies.”

If I can read the writing on the wall, this means that more manufacturing jobs will be automated out of existence, including quality improvement. In the next few years, AI will embody the quality improvement disciplines, and automate detection and autocorrection of performance problems. No human required.

But manufacturing is only 11% of U.S. employment. 80% is service industries. While quality in manufacturing is still important, the rise of service quality improvement is desperately needed in everything from healthcare to fast food.

Continue Reading "Quality 4.0 – Blog entry regarding the current trend of automation and data exchange"

Posted by Jay Arthur in Jay Arthur Blog, Manufacturing, Service, Six Sigma.

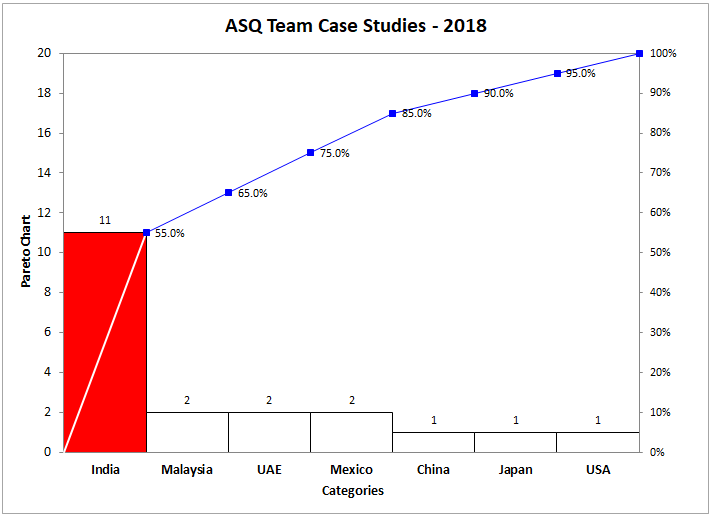

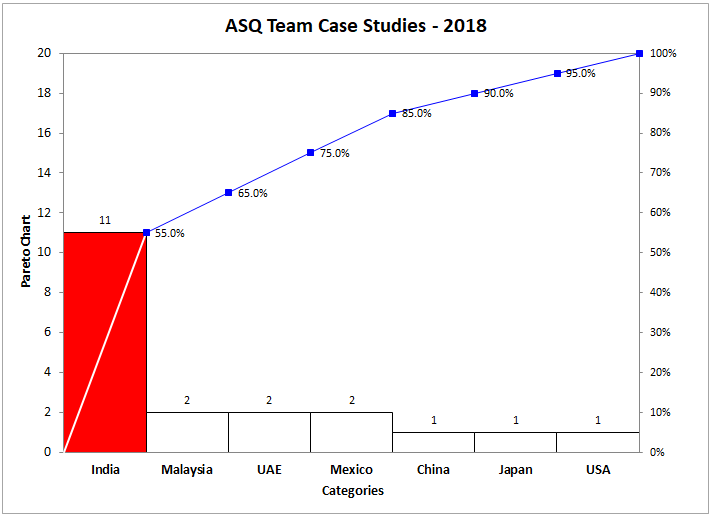

Here’s a Pareto chart of case studies by country at ASQ World 2018. Notice any trends?

Continue Reading "ASQ World 2018 – Team Case Studies"

Posted by Jay Arthur in Jay Arthur Blog, QI Macros, Six Sigma.

At ASQ LSS Conference in Phoenix, I heard an interesting presentation on digital transformation. Ben Lavoie of Anheuser-Busch asked:

How can LSS Stay relevant in a Digitally Transformed world that thrives on real-time changes?

Bad news: Need for real-time will disrupt DMAIC – leadership teams have no patience for delayed analysis and decision making

Good news: Still need people

Great news: Digital tools need LSS to solve the right problems

I think this speaks to the need for Agile Lean Six Sigma.

Ben also mentioned DevOps, how companies are integrating IT with operations in a continuous feedback loop:

I think if we substitute PDCA for the left loop and link it to operations feedback, we can get the same real-time results with Six Sigma.

Continue Reading "DevOps and QualOps"

Posted by Jay Arthur in Jay Arthur Blog.

At the ASQ Conference in Phoenix, and got some wonderful comments from one of the attendees who uses QI Macros:

Continue Reading "Testimonial from ASQ Phoenix"

Posted by Jay Arthur in Jay Arthur Blog.