Process Innovation

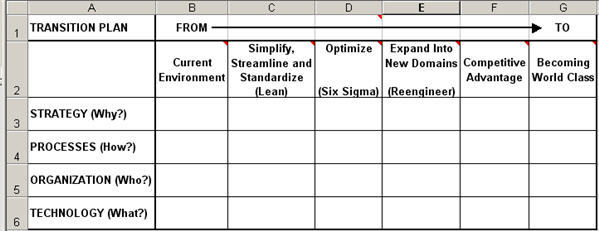

When I train companies in Lean and Six Sigma, they often ask: "Which should I do first, Lean or Six Sigma?" While my answer is often "it depends," I have found that there is a sequence that often works best. It's Lean, Six Sigma and reengineering combined. And I realized that I captured it nicely years ago in the transition planning template available in the QI Macros.

Transition Planning

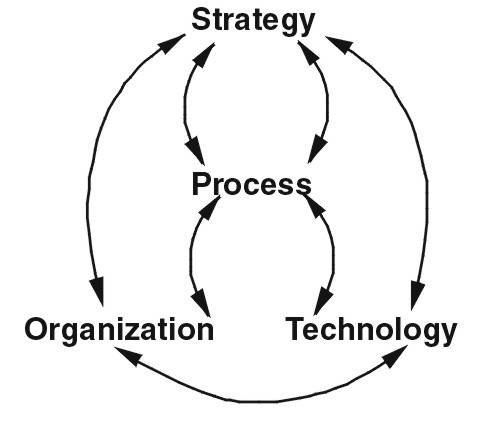

For changes to expand markets and grow the business, there is a natural flow:- Business strategy will drive changes in process. (Note: Letting process, people or technology drive strategy leads to customer and employee confusion.)

- Process changes will drive changes in organization and technology (e.g., information systems).

- Process, organization, and technology changes must be synchronized to maximize the benefits of any change. Failure to keep these in alignment will cause chaos.

- Strategy - e.g., Customer Satisfaction, Innovation, or Operational Effectiveness

- Process - How things get done.

- Organization - Who does what in the process.

- Technology - What tools are used.

Transition Planning Process

Step 1: Define the Current and World Class EnvironmentsWhat's the current way of doing business? Too manual? To slow? Too error-prone? What would a world-class version of the company look, sound and feel like?

Step 2: Simplify, Streamline and Standardize Your Processes

Use Lean. Use the 3-60 rule to mind the gaps between steps. Eliminate the delay. Eliminate the unnecessary movement of people and products. Reduce inventory. Start making things "just in time", not in advance. This alone can double your speed and cut defects in half.

Step 3: Optimize the Process

Use Six Sigma. Use the 4-50 rule to identify and mistake-proof the most error-prone steps in your process. Eliminate defects and deviation in finished goods and services. Seek to eliminate rework loops. Eliminate scrap. Eliminate the need for inspectors.

Step 4: Expand into New Domains and Markets

Reengineer. As you simplify, streamline and optimize key processes, you'll start to get ideas and insights about how to redesign these work flows for even greater efficiency and effectiveness. Do it! Make the leap to faster, better and even cheaper means of serving customers. You may also discover ways to carry these processes into new markets (e.g., UPS helping companies with not only shipping, but logistics).

I have found that simple processes invite reengineering; reengineering convoluted processes invites disaster.

Step 5: Create a Competitive Edge

Continue steps 2-4. As you collapse days of lead time into minutes or even seconds and shrink convoluted loops into small, flawless production cells, customers will sit up and take notice. The ability to do things quickly and flawlessly will create a competitive advantage that's hard to copy or beat.

Become World Class

As the improvements stack up, other companies will notice and come to benchmark your performance. That's when you'll know that you're becoming World Class.

Bravo! Keep improving. The marketplace needs your excellence to challenge everyday thinking.

Rights to reprint this article in company periodicals is freely given with the inclusion of the following tag line: "© 2008 Jay Arthur, the KnowWare® Man, (888) 468-1537, support@qimacros.com."

Take our FREE Lean Six Sigma Yellow Belt training online.

Take our FREE Lean Six Sigma Yellow Belt training online.