TLS

Theory of Constraints and Lean Six Sigma

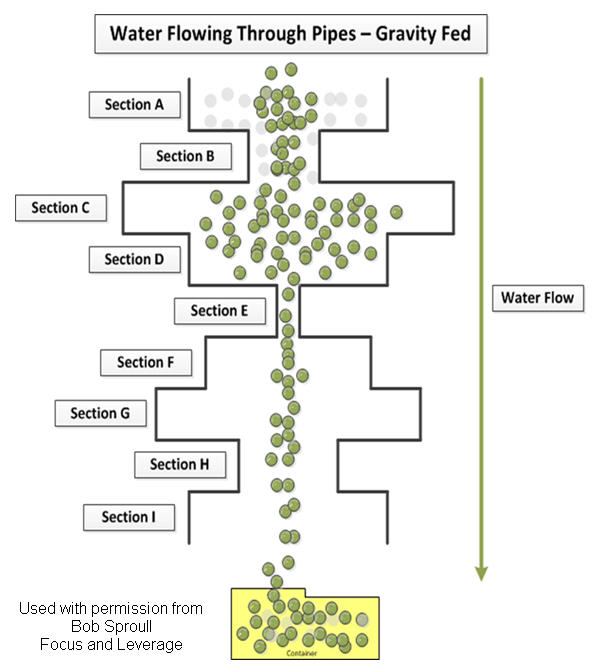

In their book, Focus and Leverage, authors Bruce Nelson and Bob Sproull offer a story of using Theory of Constraints (TOC) to Focus Lean Six Sigma improvement efforts in a hospital and in helicopter maintenance. They use water flowing through a piping diagram to illustrate the importance of constraints in controlling flow.

Piping Diagram

Where is the constraint?

As you can see, it doesn't matter how much you apply Lean Six Sigma to the processes before or after the constraint (Section E). It's the constraint that determines productivity.

Constraints and Throughput

While some companies become overly concerned with efficiencies, making the sections before or after the constraint more "efficient" will not help. You have to expand the constraint.

People often use Lean Six Sigma to simplify, streamline and optimize some portion of the business, but fail to deliver a return on investment. As you can see from this example, focusing on any other section than Section E, will not improve throughput.

Get the Idea?

Where are your constraints? How can you focus on the biggest constraint to maximize return on investment.

Rights to reprint this article in company periodicals is freely given with the inclusion of the following tag line: "© 2016 Jay Arthur, the KnowWare® Man, (888) 468-1537, support@qimacros.com."

Take our FREE Lean Six Sigma Yellow Belt training online.

Take our FREE Lean Six Sigma Yellow Belt training online.